Super glue—so small, yet so mighty. Over the years, I’ve reached for that familiar little tube for countless quick fixes, crafts, and calamities. Its promise of a fast, firm bond makes it irresistible in moments of need. But for every miraculous mend, there’s been a sticky mishap or two. Here’s a detailed recount of my personal experiences with super glue, exploring where it excels and where it falters, providing insights that might just save you from your own adhesive adventures.

Super Success Stories

Fixing Cherished Ceramics: One of the shining moments for super glue in my household was when it came to rescuing a beloved ceramic mug. The handle had snapped clean off, a casualty of a crowded kitchen sink. A dab of super glue and a few patient minutes later, the mug was back in business, handle as sturdy as ever. This repair has held up beautifully, even against the rigors of daily coffee rituals.

A Lifesaver for Loose Screws: Another win was when super glue solved a perennial problem with my eyeglasses. The tiny screws in the hinges loved to loosen themselves, leading to wobbly frames and frequent trips to the optician. A minute drop of super glue on the screw threads, and they stopped their wandering ways. This quick fix extended the life of my glasses and saved both my vision and my sanity.

Crafting with Confidence: Super glue really showed its worth during a crafting session. I was assembling a model airplane, which had several small, fiddly parts that refused to stay put. Super glue came to the rescue, holding everything firmly in place. Its fast-setting nature was perfect for keeping the momentum going, turning a frustrating assembly into a triumph of model making.

Sticky Situations to Avoid

Disaster with Delicate Fabrics: On the flip side, super gel and I have had our clashes, particularly with fabrics. In a moment of desperation, I once tried to fix a tear in a favorite silk blouse with super glue. The result? A hardened mess that ruined the delicate fabric. This taught me that fabric needs flexible, fabric-friendly adhesives, something super gel simply can’t offer.

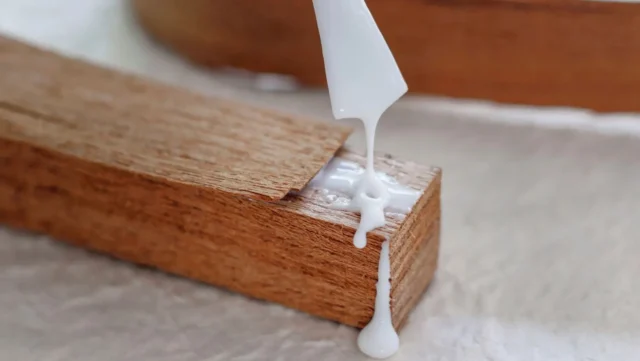

Woodwork Woes: Another misadventure occurred during a home improvement project. I attempted to use super gel to fix a loose wooden floorboard. Unfortunately, the glue didn’t adhere well to the porous wood and eventually cracked under pressure. This experience underscored that heavier, more absorbent materials require specialized wood gels that can penetrate deeply and provide a more durable bond.

Heat-Related Hassles: I also learned the hard way that super glue and high temperatures don’t mix. I had used super glue to attach a plastic knob to a metal pot lid, not considering the heat it would be exposed to. The first time I used the pot, the gel softened, and the knob came off, nearly causing a kitchen disaster. Heat-resistant adhesives would have been a safer bet for this high-temperature situation.

Lessons Learned

Know Your Surfaces: One major takeaway from my experiences is that the success of super glue greatly depends on the materials involved. Non-porous, clean surfaces are ideal for super glue. Porous or uneven materials, however, often require different types of adhesives.

Preparation Is Key: Cleaning and drying surfaces before applying super glue can significantly impact the effectiveness of the bond. Even the oil from fingerprints can prevent super glue from adhering properly.

Application Precision: Using tools like toothpicks or disposable applicators for precise application can prevent excess glue from ruining your project. Also, applying pressure to the bonded area for a few seconds can help achieve a stronger bond.

Expanding the Tool Kit: Alternative Adhesives for Different Needs

Through my trials and tribulations with super glue, I’ve learned that a well-rounded DIY toolkit includes a variety of adhesives, each suited to different types of jobs. Here’s a rundown of alternatives that have earned their keep alongside super gel on my workbench:

Epoxy Resin: For heavy-duty repairs that need to withstand stress and strain, epoxy resin is unmatched. It’s particularly effective for bonding materials like metals, ceramics, and glass where a strong, durable bond is crucial. Although it takes longer to set compared to super gel, its superior strength and resistance to temperature changes make it invaluable for complex projects.

Wood Glue: For all wood-related repairs, wood glue is the champion. Its ability to seep into the wood fibers results in a bond that is often stronger than the wood itself. Whether it’s fixing furniture or piecing together broken wooden toys, wood gel provides reliability that super glue can’t match on porous surfaces.

Fabric Glue: After the disaster with my silk blouse, I turned to fabric glue for textile repairs. It’s formulated to remain flexible, preventing the stiffness associated with super glue. For craft projects involving fabrics or quick fixes on clothing, fabric gel has proven indispensable.

Hot Glue: For crafting, especially when working with a mix of materials like paper, plastic, and light wood, hot glue guns are a go-to. The quick-setting nature and ease of use make it perfect for creative projects, although it’s not ideal for anything that requires a super-strong or heat-resistant bond.

Incorporating Proper Techniques

No matter which adhesive you choose, applying the right techniques can make a significant difference in the outcome of your projects. Here are some methods that have improved my success rate across various applications:

Surface Treatment: Beyond cleaning, sometimes roughening a smooth surface or using a primer can enhance adhesion. For plastics and metals, a light sanding can provide “teeth” for the glue to hold onto, improving the grip.

Clamping and Curing: For adhesives that take longer to set, such as epoxy or wood glue, using clamps can keep parts securely in place during the curing process. This ensures a tight bond and reduces the chance of the adhesive failing under stress.

Testing Small Areas: Before committing to gluing significant parts, especially with a new adhesive, testing on a small, hidden area can prevent a lot of grief. This test can reveal potential issues with adhesion or damage to the material.