Modern product development no longer has the luxury of time. Companies across industries are pressured to deliver faster, innovate continuously, and cut costs while keeping product quality high.

Traditional prototyping methods often fall short of these demands, relying on expensive tooling, manual labor, and weeks of waiting before a usable model is ready.

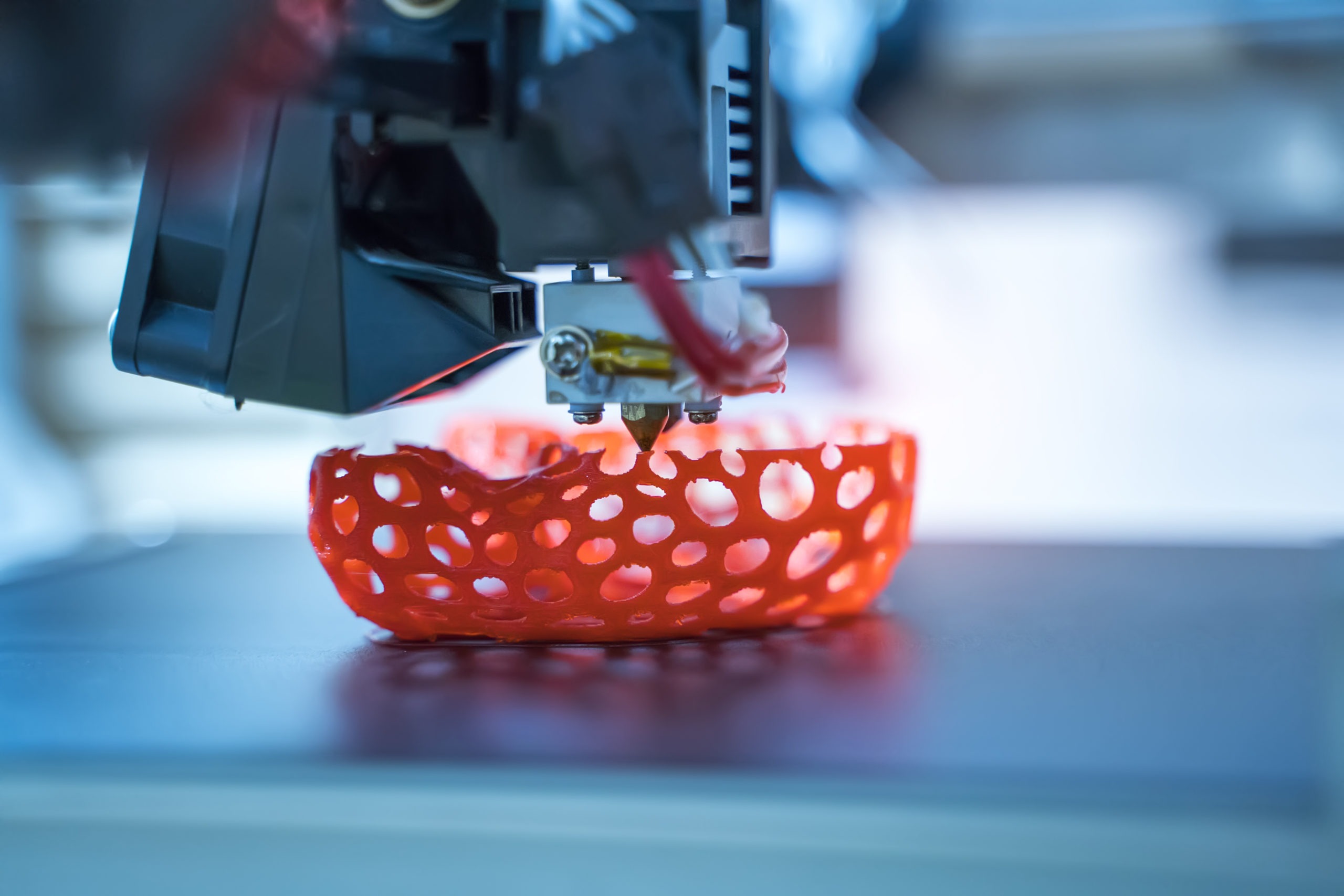

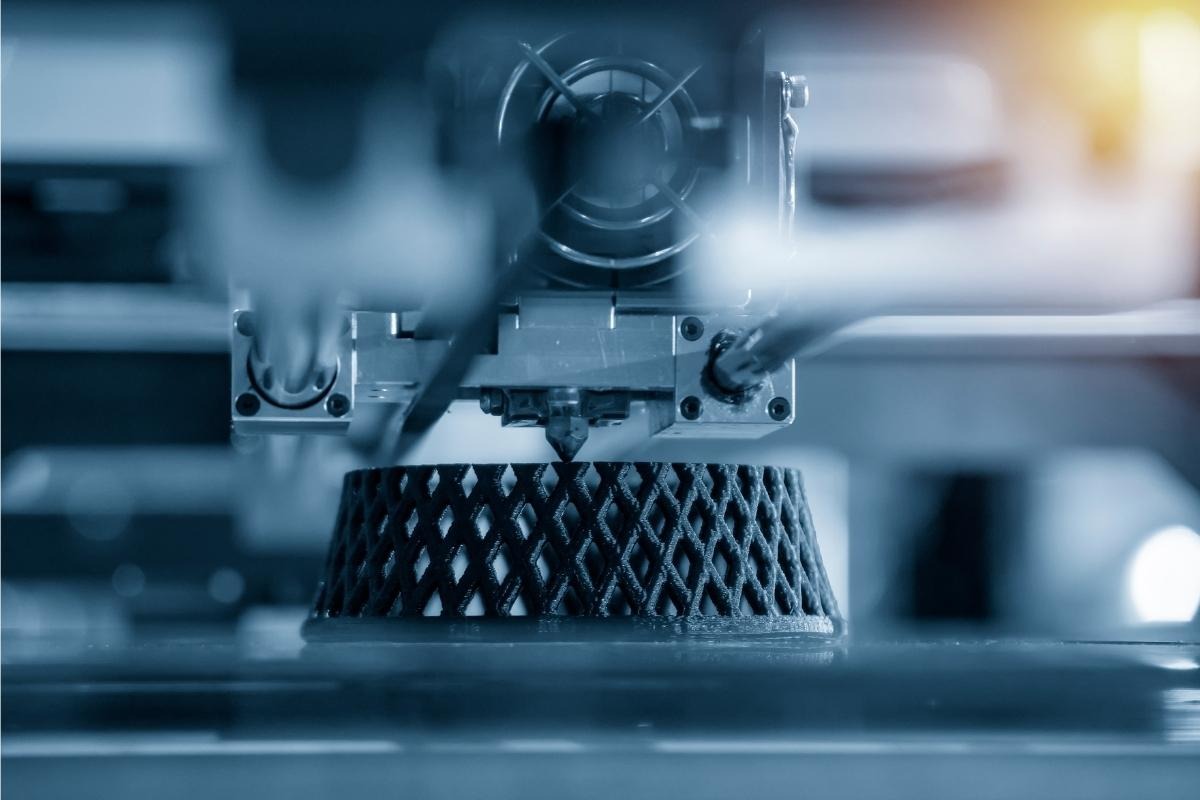

3D printing has emerged as a transformative solution. It enables rapid prototyping, greater design freedom, and seamless integration into digital workflows.

For industrial designers, engineers, and even small businesses, the technology is no longer optional – it is becoming a standard tool for competitiveness.

Faster Prototyping Means Faster Decisions

One of the clearest advantages of 3D printing lies in speed. Traditional prototypes often required outsourcing to machining shops or waiting for mold fabrication.

That meant weeks before a design team could hold a physical model in their hands. By then, market conditions might already have shifted, or competitor products could have advanced.

With 3D printing, prototyping is reduced to a matter of hours. A digital file can be sent directly to the printer, and by the next day, a team is testing shape, fit, and usability. Faster prototyping means faster decisions: whether to refine, move forward, or pivot entirely.

Take automotive design as an example. Car manufacturers once relied on clay models and slow fabrication processes.

Today, they can print full-scale components, such as dashboard panels or ventilation parts, test them in-car, and reprint adjustments within the same week.

This ability saves months in the development cycle and can be the difference between leading the market and falling behind.

From Sketches to Real Objects

Ideas often start on paper. For designers, the hardest part is turning a sketch into something tangible enough to evaluate. The connection between digital and physical design has never been more streamlined.

With tools like image to 3d model, sketches or photographs can be converted into detailed 3D files suitable for printing.

This workflow has two big benefits:

- Eliminates manual re-modeling: no need to redraw sketches in CAD from scratch.

- Speeds creative iteration: every variation can be digitized and printed for real-world testing.

Consider product packaging design. A team can photograph a hand-drawn concept, generate a printable model, and evaluate ergonomics in hand within a single day.

That kind of rapid loop fosters creativity and gives designers freedom to take risks without fearing wasted time.

The Cost Advantage for Businesses

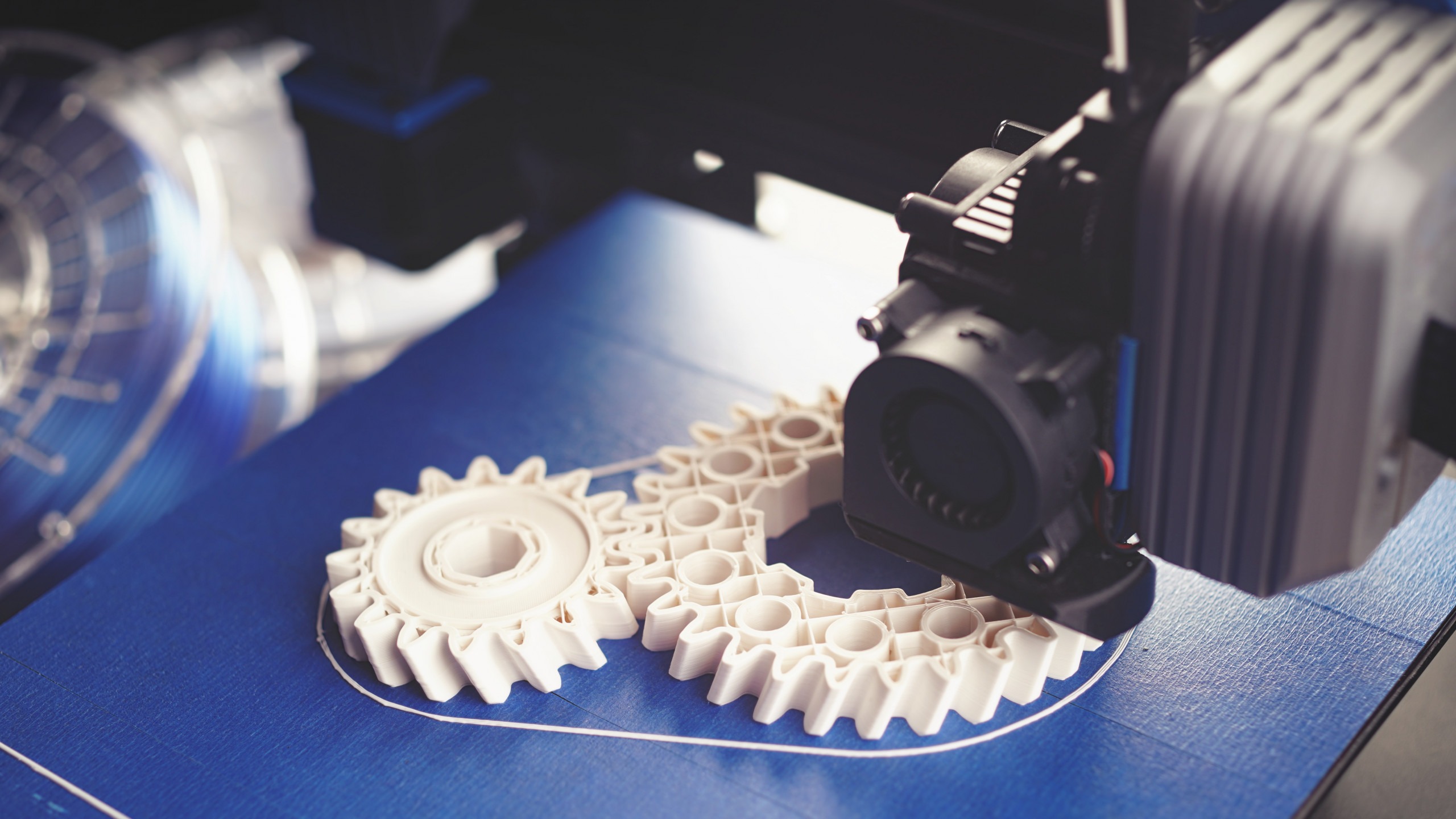

Cost efficiency may be the single most persuasive reason businesses adopt 3D printing. Traditional prototyping requires molds and machining that cost thousands of dollars, and any design change makes the initial tooling obsolete. Small companies often avoided multiple iterations simply because of budget constraints.

3D printing removes those barriers:

- No molds required: every print starts from a digital file.

- Low iteration costs: making ten versions of a part costs little more than making one.

- Reduced outsourcing: more prototyping can be done in-house, cutting lead times.

For startups, this affordability allows bold experimentation. For large corporations, it frees resources that can be reinvested into scaling production or exploring entirely new product lines.

Creative Freedom Beyond Manufacturing Limits

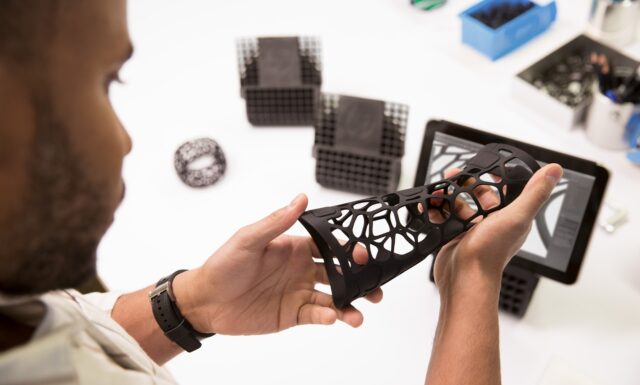

In traditional manufacturing, creativity was often tempered by what was physically possible. Thin walls, internal cavities, or complex curves were discouraged because they were costly or technically impractical. With 3D printing, those restrictions largely disappear.

Designers can now print:

- Lightweight lattice structures that save material and improve strength.

- Intricate organic shapes optimized for comfort and usability.

- Functional prototypes with moving parts in a single print.

This level of creative freedom has practical benefits. For example, aerospace companies use 3D printing to create lightweight yet strong parts that reduce fuel consumption.

Furniture designers experiment with fluid shapes that would be impossible to carve or mold. Industrial design is no longer bound by yesterday’s limitations.

Customization and Client Responsiveness

Consumers increasingly expect products tailored to their needs. In the medical industry, this might mean prosthetics fitted to a patient’s unique anatomy. In consumer goods, it could mean footwear personalized for comfort or aesthetics.

3D printing allows prototypes – and eventually final products – to be made to exact specifications without lengthy delays.

This strengthens client relationships. Imagine showing a client a prototype of a chair not in a generic size but built to their requested measurements. Approval cycles shrink, and satisfaction rises.

In fast-moving markets, customization is not just a benefit; it is a competitive necessity. Businesses that can deliver tailored designs quickly are the ones that stay ahead.

Integration with Modern Digital Workflows

3D printing’s true power comes when it is integrated into a larger digital ecosystem. A typical design-to-print process looks like this:

- Conceptualization: an idea sketched or created in CAD.

- Simulation: digital stress tests predict durability and performance.

- Conversion: files generated for 3D printing, sometimes directly from images.

- Printing: functional prototypes built within hours.

- Feedback loop: refinements made, reprinted, and tested again.

Collaboration is enhanced by cloud platforms where teams across the globe can view models, tweak parameters, and track prototypes in real time. This connectivity fits perfectly into today’s distributed industries, where design and manufacturing often happen on different continents.

Sustainability as an Added Benefit

Sustainability is no longer just a marketing term; it is a driving factor in product development. Traditional subtractive manufacturing methods waste large amounts of raw material. In contrast, 3D printing is additive – material is deposited only where it is needed.

This approach reduces waste, lowers costs, and aligns with eco-friendly manufacturing goals. Some companies are going further by experimenting with recycled plastics, biodegradable resins, or reusable metal powders.

In industries under pressure to cut emissions and demonstrate greener practices, adopting 3D printing is both environmentally and strategically wise.

Current Challenges and Future Potential

No transformative technology is without hurdles. In 3D printing, these include:

- Print speeds remain slow for very large objects.

- Limited materials for highly specialized industrial needs.

- The need for post-processing to achieve smooth finishes.

Yet the pace of innovation is solving these problems. High-speed industrial printers are entering the market, hybrid materials are expanding options, and automated finishing tools are improving quality.

Looking forward, these advancements will make 3D printing even more essential to industrial design, not just in prototyping but in full-scale manufacturing.

Conclusion

3D printing has redefined the way designers and engineers approach product development. It offers speed, affordability, creative freedom, customization, and sustainability – all qualities that align with the demands of modern industries.

For businesses, adopting 3D printing is not simply about keeping up with technology; it is about future-proofing their operations.

The message is clear: in industrial design and prototyping, 3D printing is no longer an optional tool. It is a necessity for staying competitive, innovative, and responsive in a world where efficiency and creativity are paramount.