If you are a car enthusiast who takes pride in their vehicle’s appearance, you know the importance of alloy wheels. These wheels enhance the overall look of your car. But what happens when these wheels get damaged? Can they ever shine like new again? The answer lies in the capabilities of diamond cutting machines.

Diamond cutting machines are modern marvels in the world of vehicle maintenance. They use advanced technology to repair and refurbish alloy wheels. For further information on diamond cutting machines please read on to learn more. Here, we will explore their mechanics and see how they work wonders on alloy wheels.

Benefits of Using Diamond Cutting Machines

Diamond cutting machines are important in the world of construction and manufacturing. These machines use diamonds, one of the hardest materials on Earth, to cut various materials. Here are five key benefits of using diamond cutting machines:

1. Incredible Durability:

One of the biggest benefits of diamond cutting machines is their durability. Diamonds are incredibly hard, which means they can cut through almost anything without getting damaged. This makes diamond cutting tools last much longer than regular tools. You won’t need to replace them often, saving you money in the long run.

2. Precision and Accuracy:

When it comes to cutting, accuracy is crucial. Diamond cutting machines offer unmatched precision. They can make very fine cuts with great accuracy. This is especially important for detailed work where every millimetre counts. With these machines, you can expect a high level of detail and accuracy in the final product.

3. Efficiency and Speed:

Time is money, and diamond cutting machines can save you a lot of it. They work incredibly fast, cutting through materials quicker than other types of cutting tools. This efficiency is a big plus for any project, as it means you can get more work done in less time.

4. Versatility:

Diamond cutting machines are not just for one type of material. They can cut through a wide range of materials, including concrete, metal, glass, and even wood. This versatility makes them a valuable asset for many different projects and industries. You don’t need different tools for different materials, which simplifies your work.

5. Improved Safety:

Safety is always a concern with cutting tools. The good news is that diamond cutting machines are safer to use than many other types. Their precision and efficiency reduce the risk of accidents and mistakes. Also, since they don’t wear out quickly, there’s less risk of breakage or malfunction while working.

The Process of Restoring Alloy Wheels using Diamond Cutting Machines

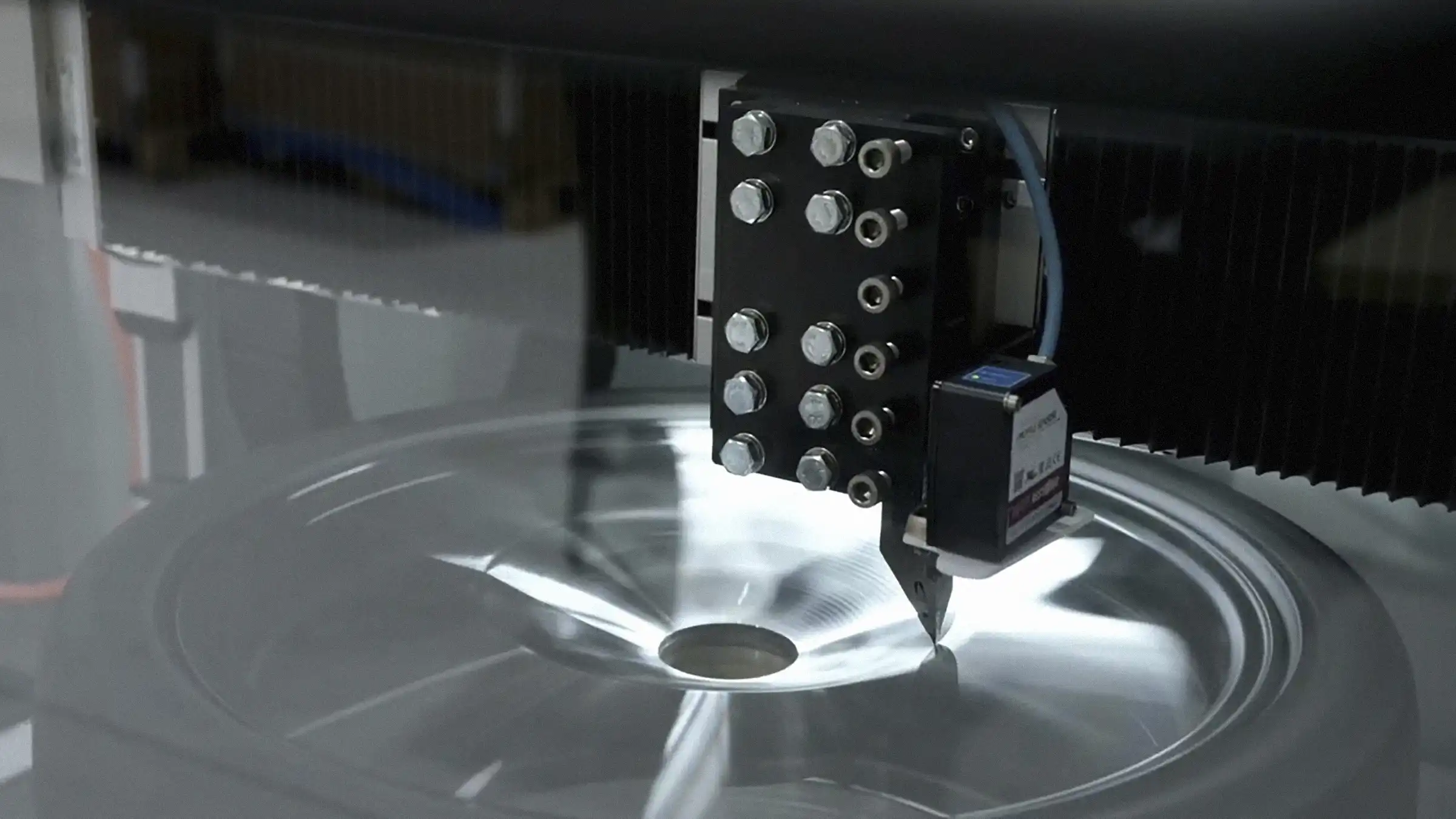

Alloy wheels can make a car look fantastic, but they can also get damaged. Whether by kerb scratches or general wear and tear, it loses its shine and appeal. The diamond cutting process involves removing a thin layer of the wheel’s surface. This action reveals a fresh layer underneath. The machine’s precision allows for the removal of just the right amount of surface material. It ensures that the wheel retains its original strength and integrity.

The process of restoring alloy wheels is quite fascinating and involves several steps.

Step 1: Wheel Inspection

The first step is to take a good look at the wheels. This is to find out what kind of damage there is. It could be scratches, dents, or corrosion.

Step 2: Cleaning

Next, the wheels are cleaned thoroughly. This is to remove any dirt, grime, or brake dust. It’s important because the wheel needs to be spotless for the next steps.

Step 3: Stripping

If the wheels are painted or coated, this layer needs to be removed. This is usually done with a strong chemical that strips off the lacquer coating. This reveals the bare alloy underneath.

Step 4: Repairing Damage

Now, it’s time to fix any damage. This might involve smoothing out scratches or filling in dents. Each wheel is carefully worked on to ensure it looks as good as possible.

Step 5: Refinishing

Once the wheels are repaired, they need to be refinished. This could involve repainting or polishing, depending on the original finish of the wheel. Some wheels might even get a diamond-cut finish, which requires a special lathe.

Step 6: Sealing

The final step is to seal the wheel with a clear coat. This protects the wheel and gives it a shiny finish. It also helps to keep it looking good for longer.

Why Seek Professional Services to Restore Damaged Alloy Wheels

When your car’s alloy wheels get damaged, it’s important to think about getting them fixed right. This is where professional alloy wheel repair services come in handy. Professionals have the right tools and know-how to assess the damage and fix it properly. They can handle all kinds of issues, from small scratches to big dents. By choosing a professional service, you make sure that your wheels are not only looking good but also safe to drive on.

Another big reason to go with professionals is cost. It might seem like doing it yourself or buying a repair kit is cheaper. But, in reality, a professional can fix your wheels for less money than it would cost to buy new ones. They also do a quality job that lasts, which means you won’t have to keep fixing the same problems over and over. In the end, having a pro fix your alloy wheels can save you both time and money, and you’ll be happier with how your car looks and drives.

Conclusion

Diamond cutting machines offer an effective solution for restoring damaged alloy wheels to their original shine. At HBC System, we understand the importance of quality and efficiency in wheel repair. Our superior-grade alloy wheel repair machine provides the highest quality finish with the quickest turnaround time available. Our alloy wheel diamond cutting machine is designed to make precise micromillimeter adjustments, ensuring that your wheels not only look their best but also maintain their structural integrity. With HBC System, you can trust that your alloy wheels are in capable hands.