PAT stands for portable appliance testing. It refers to a process that includes testing portable appliances in a competitive environment where there is a mimic of actual use. The process is taken into consideration for identifying the presence of any potential issues that can occur with the appliance. The testing is done so that the issues are controlled beforehand before they become significant issues later on.

The electronic market is growing at a tremendous rate. The platform is becoming home to an endless range of small appliances. Hence, the testing should be done with the help of sources that can ensure a quick and easy testing process.

When the question of conducting portable appliance testing comes into the picture, having PAT equipment is advantageous. There is no limit to testing any number of items in a day. Also, another advantage is that you need to establish a big lab or spend hours and days on testing only.

About The Process And Its Working

PAT testing refers to a series of testing and verification methods that help test various appliances’ efficiency. You can choose to test any appliance like a cell phone, printer, or random computer; the process will help you with what you are looking for.

The testing process can conclude within a day and be conducted by a single person.

It is a fast and reliable step that promises accuracy. You can rely on the process so that the function test is based on the requirements and sought results. The testing process is based on the principle that the appliances will not have any significant repercussions later. The operating parameters will be set if the appliance operates correctly and is connected to the power supply. Hence, the issues shall be less.

Reasons To Go For The Process

The process is comprehensive, including the performance of various electrical and functional process. It can be tested on various products that ensure conformity and compliance with safety regulations. When you do these things, it will help you in reducing the time duration which is used for determining if the product is safe for use or not.

The process renders the following benefits:

- It helps reduce the time spent investigating the safety issues that need to be addressed.

- It helps reduce the time spent inspecting the products included in the testing process.

- It helps in reducing the time spent verifying the conformity of the products.

- It helps in improving the consumers’ safety.

Testing – Items And Ideal Number

The testing system can be used for various applications, including household appliances like microwaves and irons. If your coffee maker is showing issues, you can think of finding someone who could help you with such testing.

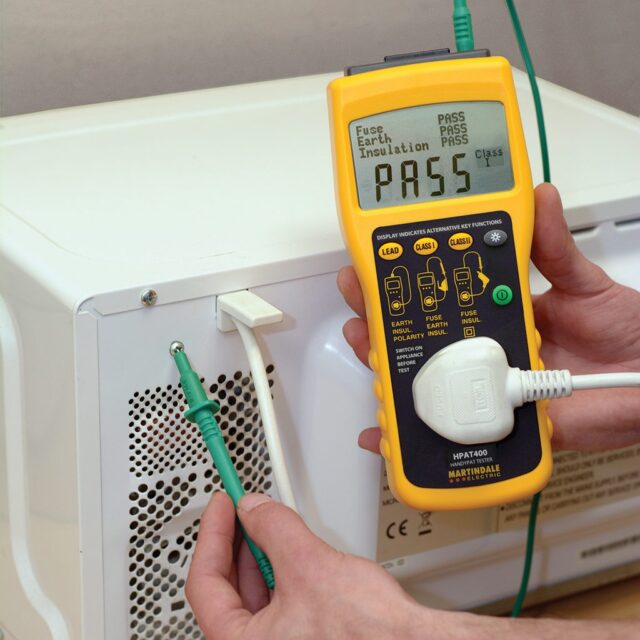

The systems that help in the testing process use a small probe attached to an electrical outlet and connect it to the appliance. The probe is helpful in testing for issues like the following:

- Voltage degree

- Flow of current

- Amperage

Apart from these, the testing steps can also be applied to the mechanical parts that are a part of the appliance that can help in understanding the resistance and the movement of the internal and external parts.

It is essential to understand that the testing process can consume time; hence, you need careful planning to conduct it correctly. When applying a portable appliance tester, it becomes easier to identify the potential issues with the devices.

The range of testing depends on the experience of the tester who is roped in for the conduction of the process. If you have an experienced and qualified PAT tester on the board during the process, the professional can average test 150 items in a day. These figures are connected to an industrial setting. However, the testing figures can reach 300 items daily if it is an office setup.

Legality Of The Process

The process is neither a legal requirement nor an obligation in itself. However, as per the ongoing legislation in the UK states, there is a need for various businesses to maintain electrical equipment and secure its functioning in a safe condition. Also, the companies functioning over there have a legal obligation to ensure the safety of the company’s employees and the general public.

However, it is essential to understand that PAT testing ensures effectiveness and becomes more important to be conducted in large environments with greater complexity. Hence, standardization of meeting this obligation comes into the picture.

There are some regulations for testing in various countries like the UK. Hence, before beginning the process, you should have an idea about the regulations that can help in the seamless conduction of the process.

Quality Requirements

The criticalness involved in the testing process is the constant need for quality assurance for various industrialists and manufacturing units. When the test is conducted, there is a need to meet specific requirements. Some of them are as follows:

- You should list the testing items followed by the requirements that need to be fulfilled for the same. It will help in the determination of the tests.

- Amid the testing process, you should create a test plan that should be an elaborated form of your notes. It can help in setting a clear focus for the testing efforts.

- However, you don’t need to get your hands on the desired results in the first go. It is different than when you should sit back and stop the process. However, you should take a step further by repeating the process. It will help you focus on the shortcomings, and also, you can identify the areas that need to be worked upon. It will help enhance the process that will also help the appliance.

Conclusion

The stage of appliance testing needs you to cater to some requirements and follow some guidelines. Nothing can hold you back if you are following a series of repetitive testing; hence, you will have the edge over quality testing. Accuracy will follow, and there will be less time wastage.